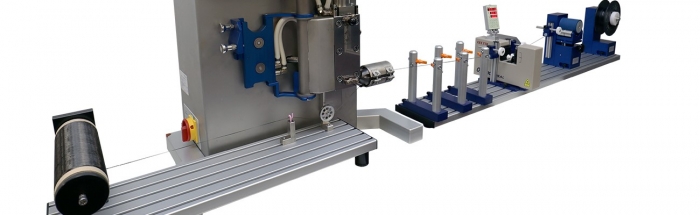

Tow Impregnation Die

The challenge with coating multifilament fibre bundles is that ideally, each filament should be wetted with a molten polymeric material to prevent inconsistencies in the material properties, leading to premature failure due to stress localisation of the end product. The Xplore TID spreads a fibre bundle inside the die, allowing the molten polymeric material to get in between each filament, hence, wetting each thread individually.

- Large operating window

- Maximum TID temperature 350 °C

- Wide range of draw rates possible

- Can be utilised with various type of fibres (e.g natural, glass and carbon)

- Saves time, material and costs

- Can be retrofitted to any MC 15 (HT) or MC 40compounder