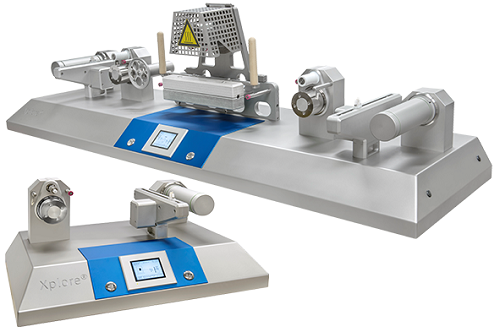

Micro Fibre Line: FL

Xplore's microfibre line enables you to obtain fibres from just 5 - 10 g of material in 10 - 15 minutes in a reliable and reproducible way. So less material is needed for testing, material development time is drastically reduced and considerably less R&D budget is needed.

Optionally a multifilament die (MFD) (see below) can be mounted onto our Xplore MC 15 compounder to have a vertical spinning die outlet, which enhances the spinning process. The MFD consists of twelve die openings to enable for multiple filament spinning applications. The MFD can be completed with a two-stage quench box and wetting ("avivage") unit and melt strength measurement to produce top quality multi-filaments.

- Smaller samples, faster sample generation. Only a fraction of material is used compared to conventional fibre development

- Continuous feeder kit. No need for an additional spinning pump, as our micro compounder is featured with throughput control to secure uniform fibre diameter

- High-speed winding unit (up to 200 m/min) and low speed stretching unit. This innovative design allows the equipment to fit on a laboratory bench

- Variable settings. Speed, overlap pitch, heating modes and other settings can be adjusted to produce diverse types of fibres

- Fibre can be heated via radiation in the "hot shoe" or via conduction with optional "hot pin"

- Selection of fibre dies

- Optional multi filament die; must be connected with our Xplore MC 15 compounder

- Optional quench box and wetting ("avivage") unit

- Optional continuous forced feeding kit; which consists of a volumetric feeder, water-cooled top hopper and elongated forced feeding screws

- *Note: One of the two units of the FL can be acquired separately

1dou1633534074.jpg)